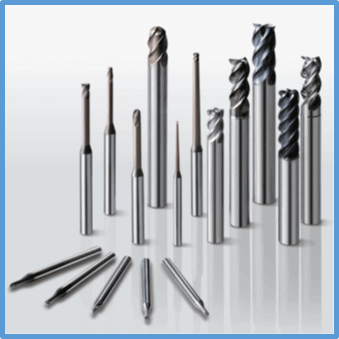

Solid Carbide Tooling

Solid Carbide Tools: Unveiling the Pinnacle

of Precision Machining

In the realm of precision engineering and

advanced manufacturing, the quest for superior tools that can withstand the

rigors of modern machining operations has led to the evolution of materials and

designs. Solid carbide tools, revered for their exceptional hardness, wear

resistance, and performance, stand as a testament to the relentless pursuit of

excellence in tooling technology. This article delves deep into the intricacies

of solid carbide tools, elucidating their properties, applications, and transformative

impact on the world of machining.

1.

Introducing Solid Carbide Tools

Solid carbide tools, as the name implies,

are cutting tools crafted entirely from carbide—a composite material renowned

for its unparalleled hardness and durability. By leveraging the unique

properties of carbide, these tools offer superior performance and longevity

compared to their traditional counterparts.

2. The

Chemistry Behind Carbide

Carbide, often a combination of tungsten (W) or titanium (Ti) with

carbon (C), forms a compound characterized by its:

● Exceptional Hardness: Resists wear and

deformation, ensuring prolonged tool life.

●

High

Thermal Stability: Maintains integrity at elevated temperatures, crucial for

high-speed machining operations.

● Chemical Inertness: Resists chemical

reactions, facilitating machining of a diverse range of materials without tool

degradation.

3. Advantages of Solid Carbide

Tools

The utilization of solid carbide tools offers a plethora of benefits:

● Extended Tool Life: Superior wear

resistance translates to reduced tool replacements and associated downtime.

●

Enhanced

Surface Finish: Produces smoother finishes, minimizing post-processing and

enhancing component aesthetics.

●

Optimized

Performance: Enables higher cutting speeds and feeds, enhancing productivity

and efficiency.

● Versatility: Accommodates a wide range of

materials, from soft alloys to hardened steels and exotic metals.

4. Applications Across

Industries

Solid carbide tools find widespread applications across various

industries, including:

● Aerospace Engineering: Facilitating the

machining of complex components with stringent tolerances and quality

requirements.

●

Automotive

Manufacturing: Enabling the production of precision parts, from engine

components to intricate assemblies.

● Medical Device Production: Catering to the

fabrication of intricate instruments and implants, demanding unparalleled

precision and reliability.

5. Innovations and Future

Trends

The evolution of solid carbide tools continues to shape the future of

machining:

● Advanced Coatings: Integration of

specialized coatings, such as titanium nitride (TiN) or diamond-like carbon

(DLC), further enhancing performance and longevity.

●

Customized

Tooling Solutions: Tailoring tools to specific applications and materials,

optimizing performance and efficiency.

● Integration with Smart Technologies:

Incorporation of sensor technology and data analytics, enabling real-time

monitoring and optimization of machining processes.

Conclusion

Solid

carbide tools, with their blend of exceptional properties and innovative

design, epitomize the pinnacle of precision machining technology. As industries

continue to push the boundaries of innovation and excellence, the role of solid

carbide tools as indispensable assets in modern manufacturing remains

unequivocal. Through their transformative impact on machining performance and

reliability, solid carbide tools reaffirm the timeless principles of precision,

efficiency, and innovation, underscoring their indispensable role in shaping

the future of manufacturing.