PCD Reamers

Brands

PCD Reamers: Revolutionizing Precision

Machining with Diamond Technology

In the ever-evolving landscape of precision

engineering and advanced manufacturing, the pursuit of superior tools that can

deliver unparalleled accuracy and performance remains paramount. PCD

(Polycrystalline Diamond) reamers, distinguished by their diamond-enhanced

cutting edges, stand at the forefront of this technological revolution. This

article delves into the intricacies of PCD reamers, elucidating their design,

applications, and transformative impact on the world of precision machining.

1.

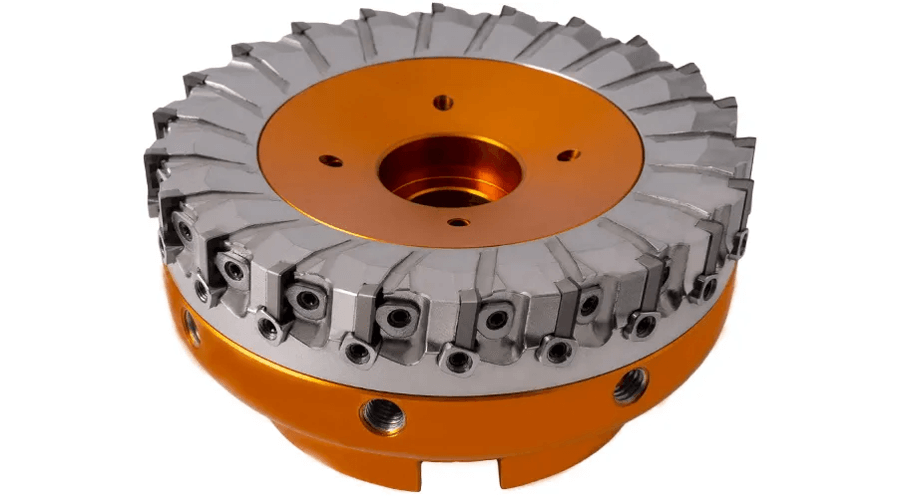

Introducing PCD Reamers

PCD reamers represent a pinnacle in cutting

tool technology, leveraging the extraordinary hardness and wear resistance of

polycrystalline diamonds to deliver exceptional performance in reaming

operations. By integrating diamond particles into the cutting edges, these

reamers offer a unique blend of durability, precision, and longevity.

2.

Unraveling the Diamond Advantage

The incorporation of polycrystalline diamonds endows PCD reamers with

unparalleled properties:

● Extreme Hardness: Diamond, renowned as the

hardest naturally occurring material, ensures superior wear resistance and

prolonged tool life.

●

Chemical

Inertness: Resistant to chemical reactions, facilitating machining of a diverse

range of materials without tool degradation.

●

High

Thermal Conductivity: Efficiently dissipates heat, minimizing thermal

deformation and ensuring consistent performance.

● Low Friction Coefficient: Reduces friction

during machining, enhancing surface finish and dimensional accuracy.

● Extended Tool Life: Exceptional wear

resistance translates to reduced tool replacements and enhanced operational

efficiency.

●

Superior

Surface Finish: Produces mirror-like finishes, minimizing post-processing and

optimizing component quality.

●

Enhanced

Chip Control: Facilitates efficient chip evacuation, reducing the risk of tool

clogging and associated machining issues.

● Optimized Performance: Enables higher

cutting speeds and feeds, enhancing productivity and machining efficiency.

4. Applications Across

Industries

PCD reamers find ubiquitous applications across various industries,

including:

● Aerospace Engineering: Facilitating the

machining of complex components with stringent tolerances and quality

requirements.

●

Automotive

Manufacturing: Enabling the production of precision parts, from engine

components to intricate assemblies.

● Medical Device Production: Catering to the

fabrication of intricate instruments and implants, demanding unparalleled

precision and reliability.

5. Innovations and Future

Trends

The evolution of PCD reamers continues to shape the future of precision

machining:

● Advanced Geometries: Tailoring reamer

designs to specific applications and materials, optimizing performance and

efficiency.

●

Integrated

Cooling Systems: Incorporation of advanced cooling systems, enhancing heat

dissipation and prolonging tool life.

● Digital Integration: Leveraging data

analytics and smart technologies for real-time monitoring and optimization of

machining processes.

Conclusion

PCD

reamers, with their groundbreaking technology and unparalleled performance,

epitomize the zenith of precision machining tools. As industries continue to

push the boundaries of innovation and excellence, the role of PCD reamers as

indispensable assets in modern manufacturing remains unequivocal. Through their

transformative impact on machining performance, surface finish, and dimensional

accuracy, PCD reamers reaffirm the timeless principles of precision,

efficiency, and innovation, underscoring their indispensable role in shaping

the future of manufacturing.