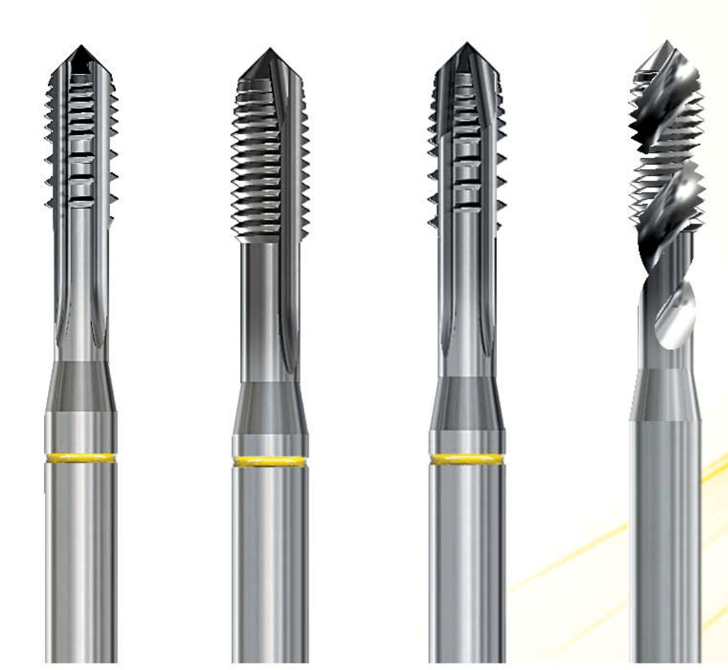

HSS Taps

Tapping: Tapping Machines and

Techniques

In the

intricate world of metalworking, the ability to create precise threads is often

the difference between success and failure. Tapping machines, with their

specialized capabilities, play a pivotal role in achieving this precision. This

article provides an in-depth exploration of various tapping machines, their

applications, and the nuances of tapping machining.

1. Understanding Tapping

Machines

A tapping

machine is a specialized tool designed to create internal threads, or taps, in

a workpiece. Unlike traditional methods that rely on manual labor, tapping

machines automate the process, ensuring consistency, accuracy, and efficiency.

2. Tapping Machining: The

Basics

Tapping machining refers to the

process of using a tapping machine to create threads. The procedure involves:

●

Drilling a Hole: Preparing the workpiece by drilling

a hole of the appropriate size and depth.

● Inserting the Tap: Mounting the tap onto the tapping machine.

●

Engaging the Tap: Initiating the tapping process,

wherein the tap rotates and cuts into the workpiece to create the desired

threads.

●

Drilling and Tapping Machine: Combines both drilling and tapping

functionalities, allowing for seamless transitioning between operations.

● Thread Tapping Machine: Specialized for creating threads, these machines ensure

precise thread pitch and depth.

● Hand Tapping Machine: Operated manually, these machines are suitable for smaller tasks and

offer greater control over the tapping process.

● Electric Tapping Machine: Powered by electricity, these machines automate the tapping

process, enhancing speed and consistency.

● Automatic Tapping Machine: Fully automated machines that can perform multiple tapping

operations without manual intervention, ideal for high-volume production.

●

Pneumatic Tapping Machine: Utilizes compressed air to drive the

tapping action, offering rapid tapping speeds and reduced operator fatigue.

●

Consistency: Ensures uniform thread quality

across multiple workpieces.

● Efficiency:

Reduces tapping time, leading to faster production rates.

● Accuracy:

Minimizes errors and inconsistencies associated with manual tapping.

●

Versatility: Accommodates a wide range of

materials and thread sizes, from delicate components to robust structures.

5. Applications of Tapping Machines

Tapping machines find widespread

applications across various industries:

●

Automotive: Creating threads in engine

components, chassis, and transmission parts.

● Aerospace:

Precision threading in aircraft components, ensuring structural integrity and

performance.

● Construction:

Fabricating threaded rods, bolts, and fasteners for infrastructure projects.

●

Manufacturing: Catering to diverse needs, from

intricate electronic components to heavy machinery parts.

Tapping machines, with their advanced

capabilities and versatility, have revolutionized the realm of threading

operations. Whether you're dealing with a hand tapping machine for intricate

tasks or an automatic tapping machine for high-volume production, the

underlying principle remains the same: precision and efficiency. As industries

continue to evolve, tapping machines will undoubtedly remain a cornerstone in

the quest for perfection in metalworking applications.