Clamping Systems

Clamping Systems

A clamping system is a

fundamental component in manufacturing and machining operations, designed to

securely hold workpieces or tools in place during machining processes. The

effectiveness of a clamping system directly influences the accuracy, repeatability,

and quality of the finished components.

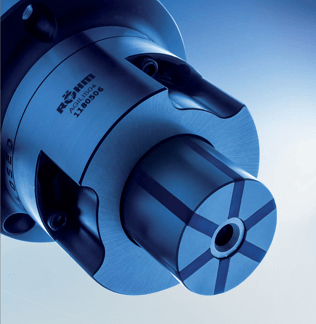

Hydraulic Clamping System

A hydraulic clamping system

utilizes hydraulic pressure to exert a controlled and uniform clamping force on

workpieces or tools. This type of system offers advantages such as high clamping

force, precise control, and rapid actuation, making it suitable for

applications requiring secure and consistent clamping, such as heavy-duty

machining operations and high-speed machining centers.

Auto Clamping System

An auto clamping system,

often integrated with advanced machining equipment, employs automated

mechanisms to facilitate quick and efficient clamping of workpieces or tools.

These systems typically utilize pneumatic, hydraulic, or electric actuators

controlled by programmable logic controllers (PLCs) or computer numerical

control (CNC) systems, enabling seamless integration with automated

manufacturing processes.

In summary, clamping systems play a pivotal role in ensuring the

stability and precision of machining operations. Whether utilizing hydraulic

systems for robust applications or embracing automated solutions for enhanced

efficiency, selecting the appropriate clamping system is crucial for achieving

optimal performance and productivity in manufacturing environments.