Boring Bars

Boring Bars : Boring bars types and

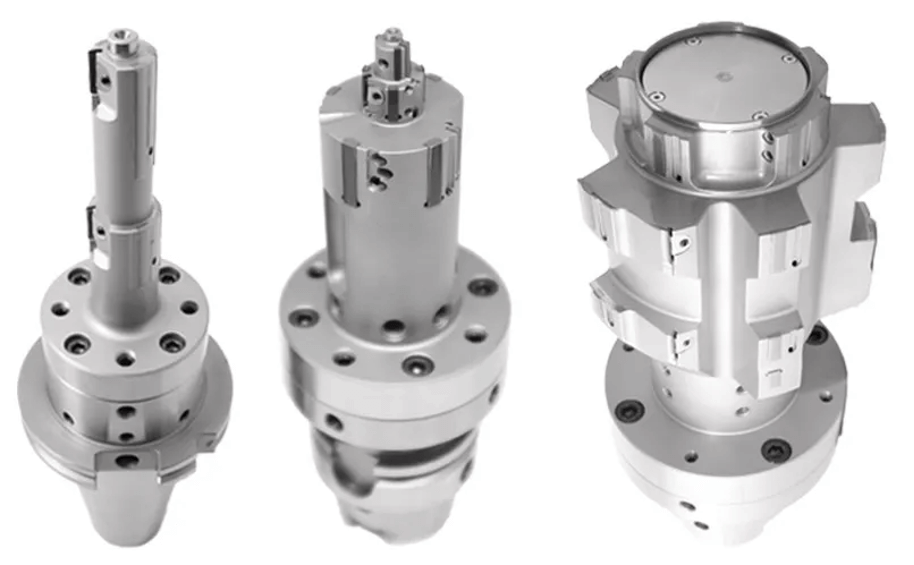

accessories

In the intricate realm of precision

engineering and advanced manufacturing, the quest for tools that can navigate

the complexities of internal machining operations with finesse and accuracy is

paramount. Boring bars, in their various configurations and designs, stand as

stalwarts in this endeavor, facilitating the creation of precise bores and

internal features with unparalleled efficiency. This article delves into the

intricacies of boring bars, elucidating their design, applications, and

transformative impact on the world of precision machining.

1.

Introducing the Boring Bar

A boring bar is a cutting tool typically

used in conjunction with a lathe or machining center to enlarge or refine

existing holes or bores. Characterized by its slender profile and unique

geometry, a boring bar enables access to internal features, ensuring precision

and accuracy in machining operations.

2. VMC

Boring Bar: Bridging Versatility and Precision

In the context of Vertical Machining Centers (VMCs), a VMC boring bar

emerges as a specialized tool tailored for vertical machining applications. By

leveraging the capabilities of a VMC, these boring bars facilitate:

● Enhanced Flexibility: Adaptable to a

diverse range of machining scenarios, from simple bores to intricate internal

profiles.

● Optimized Performance: Ensuring consistent

and repeatable results across various materials and geometries.

3. Boring Bar Tool: The Heart

of Internal Machining

A boring bar tool, with its cutting edge geometry and material

composition, serves as the linchpin of internal machining operations:

● Material Selection: Crafted from high-speed

steel, carbide, or specialized alloys, ensuring optimal performance and

longevity.

●

Geometry

Optimization: Tailored to specific applications, facilitating efficient chip

evacuation, reduced tool wear, and enhanced surface finish.

● Tool Life Enhancement: Incorporating

advanced coatings and treatments to prolong tool life and minimize maintenance.

4. Boring Bar Tool Holder:

Ensuring Stability and Precision

The synergy between a boring bar and its tool holder is pivotal in

achieving optimal machining performance:

● Rigidity: Ensuring minimal deflection and

vibration, crucial for achieving tight tolerances and surface finish

requirements.

●

Adaptability:

Accommodating a variety of boring bar designs and geometries, facilitating

seamless integration into machining setups.

● Secure Clamping: Leveraging advanced

clamping mechanisms to ensure tool retention and stability during high-speed

machining operations.

5. DCMT Boring Bar: Navigating

the Complexity of Turning Operations

The DCMT (Diamond Coated Multi-Tip) boring bar, characterized by its

diamond-coated inserts, offers a unique blend of durability and performance:

● Enhanced Wear Resistance: Diamond coatings

mitigate wear and prolong tool life, ensuring consistent performance over

extended machining cycles.

●

Superior

Surface Finish: Facilitating the production of mirror-like surface finishes,

minimizing post-processing and enhancing component quality.

● Versatility: Catering to a wide range of

materials and applications, from soft alloys to hardened steels and exotic

metals.

Conclusion

Boring

bars, with their myriad configurations and designs, epitomize the confluence of

precision engineering and advanced tooling technology. As industries continue

to push the boundaries of innovation and excellence, the role of boring bars

and their associated tool holders in facilitating intricate internal machining

operations remains unequivocal. Through their transformative impact on

machining performance, surface finish, and dimensional accuracy, boring bars

reaffirm the timeless principles of precision, efficiency, and innovation,

underscoring their indispensable role in shaping the future of manufacturing.